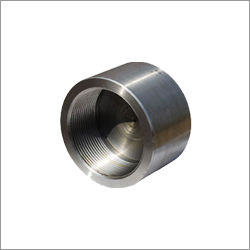

Forged Tee

Product Details:

- Sealing Type Metal-to-Metal

- Tensile Strength 485 MPa

- Yield Strength 250 MPa

- Temperature Range -20C to 600C

- Tolerance 0.05 mm

- Diameter 1/8 to 4

- Coating Type Zinc / Black

- Click to view more

Forged Tee Price And Quantity

- 100.00 - 200.00 INR/Set

- 100 Set

- 80 INR/Set

- Class 2000, 3000, 6000, 9000

- High Precision

- High

- Hydrostatic & Dimensional Inspected

- Drop Forged

- Wooden Boxes / Carton Pack

- Female

Forged Tee Product Specifications

- 485 MPa

- Sch 10 to Sch 160, XXS

- 250 MPa

- -20C to 600C

- High-pressure piping systems

- Metal-to-Metal

- Tee (T-shaped)

- 1/8 to 4 (3.18 mm to 101.6 mm)

- Socket Welded / Threaded

- Round

- NPT / BSP

- Black Painted, Galvanized, Anti-rust Oil

- Standard

- Rigid

- Socket Weld / Threaded

- Silver/Grey/Black

- Stainless Steel, Carbon Steel, Alloy Steel

- Forged Tee

- ASTM A105 / A182 F304, F316, F11, F22

- ASME B16.11 / MSS SP-83 / BS3799

- 1/8 to 4

- 0.05 mm

- 2000/3000/6000/9000 PSI

- Oil & Gas, Petrochemical, Power, Shipbuilding

- Zinc / Black

- Class 2000, 3000, 6000, 9000

- High Precision

- High

- Hydrostatic & Dimensional Inspected

- Drop Forged

- Wooden Boxes / Carton Pack

- Female

Forged Tee Trade Information

- Vadodara , Gujarat

- Letter of Credit (L/C), Cash in Advance (CID), Letter of Credit at Sight (Sight L/C)

- 1000 Set Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- Asia, South America, Western Europe, Central America, Eastern Europe, Middle East, Australia

- All India

Product Description

Forged Tee is available in diverse specifications and suitable for fitting into joints. It is widely used in residential and commercial areas for fitting pipelines. This tee is made under the guidance of our expert professionals by using latest technologies keeping in mind the set quality norms. Further, it is checked by our quality controller on different quality parameters before delivering to our valued customer ends. Our offered Forged Tee is known for their unique features like durability, impeccable finish and rust resistance.

Specification :

| Surface Finishing | Powder Coated |

| Application | Chemical Fertilizer Pipe |

| Material | Stainless Steel |

| Size | 1/2 Inch to 24 Inch |

- Type: Socket weld (s/w) & screwed (scrd) - npt, bsp, bspt

- Range: Forged fittings 15 nb to 100 nb in 2000 lbs, 3000 lbs, 6000 lbs, 9000 lbs available with nace mr 01-75.

- Form: Elbow, tee, union, coupling, cap, nipple, bush, plug, hydraulic fittings

- Features : Dimensional accuracy, Corrosion resistance, Excellent finish, High efficiency, Durable

- Stainless Steel Forged Fittings :Standard : ASTM / ASME A/SA 182

- Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

- Duplex Steel Forged Fittings :Standard : ASTM / ASME A/SA 182

- Grade : F 44, F 45, F51, F 53, F 55, F 60, F61

- Aluminium Forged Fittings :Standard : ASTM B247, B361.

- Grade : 2024, 6061, 6063, 6101, 7075

- Titanium Forged Fittings :Standard : ASTM B381.

- Grade : Grade 1, Grade 2, Grade 4, Grade 5, Grade 6, Grade 7, Grade 9, Grade 19, Grade 23

- Carbon Steel Forged Fittings :Standard : ASTM A 105/A694/ A350 LF3/A350 LF2.

- Grade : F42/46/52/56/60/65/70

- Low Temperature Carbon Steel Forged Fittings :Standard : ASTM A 350 LF2 / A350 LF3

- Alloy Steel Forged Fittings :Standard : ASTM A182

- Grade : F1/F5/F9/F11/F22/F91

- Copper Alloy Forged Fittings :Standard : ASTM / ASME SB 61 / 62 / 151 / 152.

- Grade : UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) C 71640

Nickel Alloy Forged Fittings :Standard : ASTM / ASME SB 564 / 160 / 472

- Nickel 200 - UNS N02200

- Nickel 201 - UNS N02201

- Monel 400 - UNS N04400

- Monel K500 - UNS N05500

- Inconel K600 - UNS N06600

- Inconel 601 - UNS N06601

- Inconel 625 - UNS N06625

- Inconel 800 - UNS N08800

- Inconel 800H - UNS N08810

- Inconel 825 - UNS N08825

- Hastelloy C276 - UNS N10276

- Alloy 20 - UNS N08020

Manufacturer Test Certificate as per EN 10204 / 3.1

Engineered for Extreme Conditions

Forged Tees are crafted to excel in volatile or high-stress environments. Withstanding temperatures from -20C to 600C and pressures up to 9000 PSI, their high corrosion resistance and exceptional strength make them a preferred choice for industries like oil & gas and petrochemical plants. These tees assure both structural integrity and reliable flow control under challenging operational demands.

High Precision and Versatility

Manufactured with high precision tolerances (0.05 mm) and available in various sizes (outer diameter 1/8 to 4 inches), Forged Tees meet ASME B16.11, MSS SP-83, and BS3799 standards. Suitable for Sch 10 to Sch 160 and XXS thicknesses, users can select from metal grades such as ASTM A105, F304, F316, F11, and F22, supporting diverse project specifications.

FAQs of Forged Tee:

Q: How are Forged Tees manufactured and what advantages does drop forging offer?

A: Forged Tees are produced via the drop forging process, where heated metal billets are shaped under high pressure to create dense, mechanically robust fittings. This technique enhances the tees grain structure, resulting in excellent strength and durability, allowing safe use under high-pressure and high-temperature conditions.Q: What are the suitable applications for these Forged Tees?

A: These Forged Tees are widely used in high-pressure piping systems across oil & gas, petrochemical, power generation, and shipbuilding industries. Their robust sealing and corrosion-resistant properties make them ideal for handling aggressive fluids and gases in demanding environments.Q: When is it recommended to use a Class 6000 or Class 9000 Forged Tee?

A: Class 6000 and 9000 Forged Tees are best utilized in extremely high-pressure applications, such as critical pipelines or processing systems in refineries, chemical plants, or power stations, where safety and leak-proof performance are paramount.Q: What materials and coatings are available for these Forged Tees?

A: Forged Tees are manufactured from various grades, including ASTM A105 (carbon steel), A182 F304 and F316 (stainless steel), F11, and F22 (alloy steel). They come with protective coatings such as black paint, galvanization, or anti-rust oil to increase corrosion resistance and ensure long service life.Q: How are the dimensions and quality of the Forged Tees assured?

A: Every Forged Tee undergoes rigorous hydrostatic and dimensional inspections, adhering strictly to ASME, MSS, and BS standards. High-precision machining guarantees dimensional accuracy within a 0.05 mm tolerance, ensuring a perfect fit for high-pressure connections.Q: Where can these Forged Tees be sourced in India?

A: Forged Tees are available through a comprehensive network of dealers, distributors, exporters, importers, manufacturers, suppliers, traders, wholesalers, and service providers throughout India, ensuring prompt delivery and technical support.Q: What are the primary benefits of using a high precision, metal-to-metal sealing Forged Tee?

A: The high precision and metal-to-metal sealing design of these tees offer exceptional leak-tightness, consistent mechanical performance, and robust resistance to high pressure and temperature variations, significantly reducing maintenance needs and enhancing system reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+