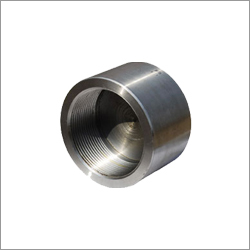

Steel Cap Fitting

120 INR/Unit

Product Details:

- Yield Strength 240 MPa

- Temperature Range -50C to +600C

- Diameter 21.3 mm 1219 mm

- Tolerance 0.5 mm

- Sealing Type Weld Seal

- Flexibility Rigid

- Connection Type Welded

- Click to view more

X

Steel Cap Fitting Price And Quantity

- 1000 , , Unit

- 120 INR/Unit

Steel Cap Fitting Product Specifications

- -50C to +600C

- 240 MPa

- Carbon Steel / Stainless Steel

- A234 WPB, SS304, SS316, A420 WPL6, etc.

- Sch 10 Sch 160, XXS

- 21.3 mm 1219 mm

- Circular

- Black Painted / Anti Rust Oil / Sand Blasted / Galvanized

- Steel Cap Fitting

- Weld Seal

- ASTM/ASME A234, ANSI B16.9, DIN2605, EN10253

- Pipe End Protection, Sealing Pipes

- Butt Weld

- 0.5 mm

- Black, Silver

- 1/2 (21.3mm) 48 (1219mm)

- Round

- 3 mm 40 mm

- Oil & Gas Industry, Petrochemical, Water Treatment, Power Plants

- Rigid

- Customized / As per requirement

- Welded

- Painted / Galvanized / Anti Rust

- 415 MPa

Steel Cap Fitting Trade Information

- Vadodara , Gujarat

- Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C)

- 1000 , , Unit Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- Western Europe, South America, Asia, Central America, Eastern Europe, Australia, Middle East

- All India

Product Description

Steel Cap Fitting is mainly used for protecting the end of pipe and other fittings. It is available in different designed and can be customized according to the shape of pipe line. Apart from this, it used in hydraulics and plumbing industries to close the end of pipes. Our offered fitting can be easily opened and closed by just a mere push and can also be availed in threaded configuration on demands. Our offered Steel Cap Fitting is checked by our quality controller on different quality parameters ensuring their flawlessness.

Specification :

| Usage/Application | Structure Pipe |

| Color | Silver |

| Size | 1/2 Inch to 24 Inch |

| Material | SS |

| Fitting Type | Threaded |

- Type: Socket weld (s/w) & screwed (scrd) - npt, bsp, bspt

- Range: Forged fittings 15 nb to 100 nb in 2000 lbs, 3000 lbs, 6000 lbs, 9000 lbs available with nace mr 01-75.

- Form: Elbow, tee, union, coupling, cap, nipple, bush, plug, hydraulic fittings

- Features :Dimensional accuracy, Corrosion resistance, Excellent finish, High efficiency, Durable

- Stainless Steel Socket Weld Fittings :Standard : ASTM / ASME A/SA 182

- Grade :F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

- Duplex Steel Socket Weld Fittings :Standard :ASTM / ASME A/SA 182

- Grade : F 44, F 45, F51, F 53, F 55, F 60, F61

- Aluminium Socket Weld Fittings :Standard :ASTM B247, B361.

- Grade : 2024, 6061, 6063, 6101, 7075

- Titanium Socket Weld Fittings :Standard :ASTM B381.

- Grade : Grade 1, Grade 2, Grade 4, Grade 5, Grade 6, Grade 7, Grade 9, Grade 19, Grade 23

- Carbon Steel Socket Weld Fittings :Standard : ASTM A 105/A694/ A350 LF3/A350 LF2.

- Grade : F42/46/52/56/60/65/70

- Low Temperature Carbon Steel Socket WeldFittings :Standard : ASTM A 350 LF2 / A350 LF3

- Alloy Steel Socket Weld Fittings :Standard :ASTM A182

- Grade : F1/F5/F9/F11/F22/F91

- Copper Alloy Socket Weld Fittings :Standard :ASTM / ASME SB 61 / 62 / 151 / 152.

- Grade : UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) C 71640

Precision Engineering & Quality Standards

Our steel cap fittings are engineered to deliver consistent tolerance (0.5 mm) and a hardness range of 170220 HB. We achieve this through rigorous manufacturing processes and adherence to international standards like ASTM/ASME A234 and EN10253. Each fitting is marked according to client specifications and subject to strict quality assurance for optimal reliability in demanding applications.

Customizable Solutions & Versatile Packing

Steel cap fittings are available in a wide variety of sizesfrom 1/2 inch (21.3 mm) to 48 inches (1219 mm) in diameter and 3 mm to 40 mm in thickness. Lengths can be customized as requested. Packing options include sturdy wooden cases, pallets, or bespoke arrangements, ensuring safe transport and handling. Products are crafted to suit the needs of dealers, distributors, exporters, importers, and service providers throughout India.

FAQs of Steel Cap Fitting:

Q: How are steel cap fittings manufactured, and what production processes are used?

A: Steel cap fittings are produced using seamless or welded methods, ensuring exceptional strength and integrity. Seamless caps are formed from solid steel billets, while welded caps are fabricated by joining steel plates or pipes. Both processes comply with relevant standards such as ASTM/ASME A234 and DIN2605.Q: What surface treatments and coatings are available for these fittings to enhance corrosion resistance?

A: Steel cap fittings can be finished with black painted, anti-rust oil, sand blasting, or galvanized coatings. These treatments improve resistance to corrosion, making the fittings suitable for harsh environments found in oil & gas, petrochemical, and water treatment industries.Q: When can I expect delivery of my steel cap fitting order, and what is the typical lead time?

A: Lead times for steel cap fittings range from 7 to 30 days after order confirmation, depending on quantity, customization requirements, and packing preferences. Standard packing options are wooden cases and pallets, or can be tailored as per request.Q: Where can these steel cap fittings be used, and which industries benefit from them?

A: Steel cap fittings are suitable for sealing and protecting the ends of steel pipelines in oil & gas, petrochemical, power generation, and water treatment plants. Their robust design ensures reliable performance in applications exposed to high pressures and temperatures.Q: What are the main benefits of using steel cap fittings in pipeline systems?

A: The primary advantages include secure sealing of pipe ends, protection against contamination or damage, and extended pipeline longevity. Their excellent tensile (415 MPa) and yield strength (240 MPa), along with corrosion resistance, make them vital for industrial pipeline safety and maintenance.Q: How can I specify marking, material grade, or other customization requirements for my order?

A: Marking, material grade, dimensions, and surface treatments can be customized based on client or project requirements. Simply provide the relevant specifications during the ordering process, and products will be manufactured in compliance with these instructions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email