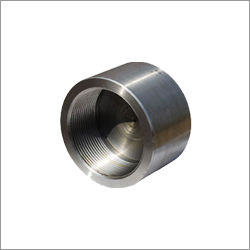

Forged Elbow Fitting

Product Details:

- Diameter DN6 to DN100

- Yield Strength 250 MPa (varies by material)

- Tolerance 0.5 mm

- Tensile Strength 485 MPa (varies by material)

- Thread Type NPT / BSPT / BSP / UNF

- Flexibility Rigid

- Coating Type Rust Preventive Coating / Electro-Galvanized

- Click to view more

Forged Elbow Fitting Price And Quantity

- 100 Set

- 110.00 - 130.00 INR/Piece

Forged Elbow Fitting Product Specifications

- Short Radius (SR) / Long Radius (LR)

- Silver, Black, Metallic Grey

- Socket Weld / Threaded (Screwed)

- -20C to 600C

- Sch 40, Sch 80, Sch 160, XXS (as per spec)

- Carbon Steel / Stainless Steel / Alloy Steel

- Forged Elbow Fitting

- Rust Preventive Coating / Electro-Galvanized

- Metal to Metal

- As per standard or custom

- Plumbing, Industrial Piping, Petrochemical, Refinery

- Black Painting / Anti-rust Oil / Sand Blasting

- Socket Weld, Threaded

- Elbow (90 / 45) Bend

- 2000LB, 3000LB, 6000LB (as per spec)

- NPT / BSPT / BSP / UNF

- Rigid

- Round

- ASME B16.11, ANSI, DIN, JIS, BS

- 1/8 to 4 (DN6 to DN100)

- 250 MPa (varies by material)

- Pipe Connection (Oil, Gas, Chemical, Water)

- ASTM A105, A182 F304, F316, F11, F22

- DN6 to DN100

- 0.5 mm

- 485 MPa (varies by material)

Forged Elbow Fitting Trade Information

- Vadodara , Gujarat

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID)

- 1000 Set Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- Middle East, Eastern Europe, South America, Western Europe, Asia

- All India

Product Description

Forged Elbow Fitting is designed to change direction as well as reduce the size of pipe within a piping system. It is made by using modern technologies under the direction of our expert professionals keeping in mind the set quality norms. It is available in different specifications as per the needs of our valued customers and can be customized as per the needs of our valued customers. These fitting are checked by our quality controller in order to provide defect free range to our valued customer ends. Our offered Forged Elbow Fitting is known for their unique features like hassle free performance and high tensile strength.

Specification

| Size | 1/2 Inch to 48 Inch |

| Material | Carbon Steel |

| Connection | Female |

| Application | Gas Pipe,Chemical Fertilizer Pipe,Hydraulic Pipe |

| End Connection Type | Buttweld |

| Elbow Bend Angle | 90 Degree,180 Degree,45 Degree |

Forged Elbows are available in Following Materials:

Stainless Steel :

- Standard : ASTM / ASME A/SA 182

- Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

Duplex Steel :

- Standard : ASTM / ASME A/SA 182

- Grade : F 44, F 45, F51, F 53, F 55, F 60, F 61

Aluminium :

- Standard : ASTM B247, B361.

- Grade : 2024, 6061, 6063, 6101, 7075.

Titanium :

- Standard : ASTM B381.

- Grade : Grade 1, Grade 2, Grade 4, Grade 5, Grade 6, Grade 7, Grade 9, Grade 19, Grade 23

Carbon Steel

- Standard : ASTM A 105/A694/ A350 LF3/A350 LF2.

- Grade : F42/46/52/56/60/65/70

Low Temperature Carbon Steel :

Standard : ASTM A 350 LF2 / A350 LF3

Alloy Steel

- Standard : ASTM A182

Grade : F1/F5/F9/F11/F22/F91

Copper Alloy :

ASTM / ASME SB 61 / 62 / 151 / 152.

Nickel Alloy :

Standard : ASTM / ASME SB 564 / 160 / 472

Nickel 200 UNS N02200 Nickel 201 UNS N02201 Monel 400 UNS N04400

Monel K500 UNS N05500 Inconel K600 UNS N06600 Inconel 601 UNS N06601

Inconel 625 UNS N06625 Inconel 800 UNS N08800 Inconel 800H UNS N08810

Inconel 825 UNS N08825 Hastelloy C276 UNS N10276 Alloy 20 UNS N08020

Precision and Durability

Our forged elbow fittings are manufactured through advanced drop forging and CNC processes, ensuring high dimensional accuracy and robust structure. These fittings maintain their integrity even under severe pressures up to 6000 LBS and temperatures ranging from -20C to 600C, providing unmatched service life exceeding 15 years under standard conditions.

Versatility in Application

Suitable for a wide range of industries, including plumbing, petrochemical, refinery, and industrial piping, these elbows are designed to connect pipes securely. They are available in 45 and 90 bends, with multiple end and thread types, enabling flexibility in installation across diverse projects.

Superior Protection and Customization

Benefit from high corrosion resistance, thanks to materials like stainless and alloy steels, coupled with protective coatings such as black painting, anti-rust oil, or electro-galvanization. Each fitting can be tailoreddimensions, surface treatment, and end connectionsto meet your exact project specifications.

FAQs of Forged Elbow Fitting:

Q: How are forged elbow fittings manufactured to ensure durability and precision?

A: Our forged elbow fittings are manufactured using a drop forging process, followed by heat treatment and CNC machining. This combination results in excellent mechanical properties, tight tolerances (0.5 mm), and a strong, leak-proof design suitable for high-pressure applications.Q: What materials and surface treatments are available for these elbows?

A: We offer elbows in carbon steel, stainless steel, and alloy steel, complying with standards like ASTM, ASME, and DIN. Surface treatments include black painting, anti-rust oil, sand blasting, and electro-galvanization, providing enhanced protection against corrosion and chemicals.Q: When should I use a forged elbow fitting with a specific end connection?

A: The choice between beveled, plain, or threaded endsand socket weld or threaded (screwed) connectionsdepends on your piping systems design and installation method. Threaded ends are best for frequent disassembly, while socket weld or beveled ends are ideal for permanent, high-strength connections.Q: Where can these elbows be used, and what sizes are available?

A: Our forged elbows are versatile, suitable for oil, gas, chemical, and water pipelines in plumbing, petrochemical, and industrial environments. They are available in outer diameters from 1/8 to 4 (DN6 to DN100), with custom lengths and thicknesses to meet project specifications.Q: What is the testing process prior to shipment?

A: Every fitting undergoes 100% hydrostatic and positive material identification (PMI) testing to guarantee integrity and compliance with industry standards, ensuring leak-proof and durable performance on site.Q: How does the corrosion resistance benefit long-term usage?

A: Elbows made from stainless or alloy steels, and treated with anti-corrosive coatings, remain resistant to chemicals, moisture, and temperature fluctuations. This significantly extends service life and reliability, minimizing maintenance and replacement costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+