High Grade SS Structural Extrusions

Product Details:

- Material Composition % Nickel 8-10%, Chromium 17-20%, Balance Iron (for 304)

- Recyclable Yes

- Corrosion Resistant Yes, highly resistant

- Size Standard and customized sizes available

- Coating Type None or as specified

- Heat Resistance Up to 870C (for 304/316 grades)

- Product Form Extruded Profile

- Click to view more

High Grade SS Structural Extrusions Price And Quantity

- 200 INR/Kilograms

- 10 , , Kilograms

High Grade SS Structural Extrusions Product Specifications

- SS304 / SS316 / SS202 (as per order)

- Frameworks, Supports, Architectural Applications

- None or as specified

- Nickel, Chromium, Manganese, Iron (Typical for stainless steels)

- Silver

- 1mm - 20mm

- Standard and customized sizes available

- Yes, highly resistant

- Extrusion

- Vary as per dimension and shape

- 304, 316, 202

- Yes

- Nickel 8-10%, Chromium 17-20%, Balance Iron (for 304)

- Polished, Matt, Brushed

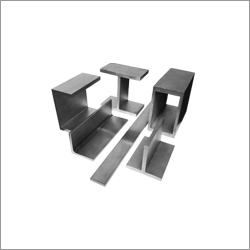

- L, T, U, I, Square, Rectangle, Custom Profiles

- Customizable as per requirement

- Bright, Matt, or Brushed Finish

- As per profile geometry

- 520750 MPa

- ASTM, JIS, DIN, EN, IS

- 160-220 HB

- Construction, Structural Support, Fabrication Projects

- Stainless Steel

- High Grade SS Structural Extrusions

- Extruded Profile

- Up to 870C (for 304/316 grades)

High Grade SS Structural Extrusions Trade Information

- Vadodara , Gujarat

- Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cash in Advance (CID), Letter of Credit (L/C)

- 100000 , , Kilograms Per Week

- 1 Days

- Yes

- Contact us for information regarding our sample policy

- Eastern Europe, Western Europe, Middle East, Asia

- All India

- Yes

Product Description

SS Structural Extrusions

We have become the industry leader in exporting and importing premium grade SS Structural Extrusions that is processed by squeezing of metals into a encompassed cavity through a respective tool, known as a die using either a hydraulic or mechanical press. This is how long straight metal parts are produced through our extrusions. In addition, our machine helps in minimizing the need for additional machinery and ensures perfect dimensional accuracy and surface finish. Our SS Structural Machine is used to process materials such as lead, tin and alloys. The machine offered by us promises no oxidation and has excellent mechanical properties.

TYPE : 202, 304, 304L, 304, 304H, 316, 316L, 316Ti, 321, 321H, 317, 317L, 310, 310S, 409, 410, 420, 430 etc.

OTHER :

- HYDRAULIC TUBE

- CAPILLARY TUBE

- HORN TUBE

- BOILER TUBE

- IBR TUBE

- PRECISION TUBE

Stainless Steel Structural's :

ASTM A 312, A 213, A 213, A 249, A 269, A 358, A 240, A 276

Carbon Steel Structural's :

ASTM A 106, A 53, API A 5L Gr A, B, C, ASTM A 333, Gr 1 to 6 (IBR & NON IBR)

Alloy Steel Structural's :

ASTM A 335, GR P1, P2, P5, P9, P11, P22, P91

Copper Alloy Structural's :

Aluminium, Copper, Brass & Gunmetal

Nickel Alloys Structural's :

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy 904, Titanium, Tungston, SIlver Nickel, Zirconium, Palladium, Vanadium etc

Size of Angles :

- 20 mm x 20 mm x 3 mm Thk.

- 25 mm x 25 mm x 3 mm Thk.

- 25 mm x 25 mm x 5 mm Thk.

- 30 mm x 30 mm x 3 mm Thk.

- 100 mm x 100 mm x 12 mm Thk. Etc.

Precision Engineering and Versatility

Our High Grade SS Structural Extrusions offer a broad choice of profiles, including L, C, Z, T, and I-Beam, as well as custom shapes. Manufactured from stainless steel grades 304, 316, and 202, they are suitable for diverse structural, architectural, and industrial applications, thanks to their robust mechanical properties and tailored configurations.

Superior Chemical and Corrosion Performance

Designed to stand up to a wide spectrum of chemicals, our extrusions are highly resistant to acids, alkalis, and chlorides. The corrosion resistance varies with grade but meets rigorous requirements for both indoor and outdoor environments, making these products a reliable choice for demanding projects.

Excellent Weldability and Machinability

These structural extrusions are readily weldable by standard methods, enabling easy assembly on-site. Their good machinability ensures they can be efficiently bent, cut, or drilled to meet precise project needs, streamlining fabrication and installation for customers.

Reliable Delivery and Custom Packaging

Every order is packaged in export-worthy materials, such as sturdy wooden boxes, or as tailored to client specifications. Lead times are typically 2-4 weeks after order confirmation, and minimum order quantities are determined by mutual agreement, ensuring supply flexibility.

FAQs of High Grade SS Structural Extrusions:

Q: How are High Grade SS Structural Extrusions manufactured?

A: These extrusions are produced using processes such as hot rolling, cold drawing, or extrusion, depending on the specific dimensions and mechanical requirements. This results in strong, dimensionally accurate, and uniform products suitable for structural and architectural use.Q: What are the main advantages of using these stainless steel extrusions?

A: High Grade SS Structural Extrusions offer superior corrosion and chemical resistance, excellent weldability, and good machinability. They are non-magnetic in annealed conditions (for 304 and 316) and withstand a broad temperature range, making them highly versatile for various frameworks and support structures.Q: When should I choose grade SS304, SS316, or SS202?

A: Grade selection depends on the environment and desired properties. SS304 is an all-purpose grade with robust corrosion resistance, SS316 is preferred where higher resistance to chlorides or acids is needed, and SS202 is suitable for less aggressive settings. All grades can be chosen based on application requirements and cost considerations.Q: Where are these extrusions commonly used?

A: They are widely employed in construction, structural support, fabrication projects, architectural frameworks, and infrastructure works. Customizable sizes and profiles enable their integration into a variety of industrial and commercial projects.Q: What is the minimum order quantity and lead time for these products?

A: The minimum order quantity (MOQ) is determined by mutual agreement based on your requirements. The standard lead time for delivery is 2 to 4 weeks following order confirmation, ensuring prompt and reliable service.Q: How are the extrusions packaged for export and safe delivery?

A: Products are securely packed in export-worthy materials, typically wooden boxes, but can be packed per customer specification to prevent transit damage and facilitate easy handling.Q: What surface finishes are available, and can the edge type be customized?

A: Surface options include polished, matt, or brushed finishes, and the edge type can be supplied as smooth/straight cut or tailored to project demands. Finishing and edge customization ensure compatibility with aesthetic and technical requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+