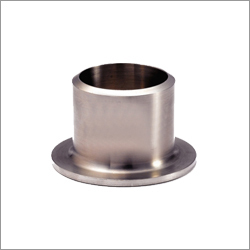

Stubend Fitting

110 INR/Unit

Product Details:

- Diameter 1/2 to 24 (as per requirement)

- Heat Resistance Up to 870C (for 304/316 grades)

- Coating Type None (Bare/Polished Surface)

- Product Form Stub End

- Tensile Strength 515 MPa (for 304 grade)

- Size Standard and customized sizes available

- Material Composition % Cr: 18-20%, Ni: 8-12%, Mo: 2-3% (316/316L grades)

- Click to view more

X

Stubend Fitting Price And Quantity

- 110 INR/Unit

- 1000 , , Unit

Stubend Fitting Product Specifications

- Stainless Steel alloyed with Cr, Ni, Mo (as per grade)

- 1/2 to 24 (as per requirement)

- Stubend Fitting

- Up to 870C (for 304/316 grades)

- Polished / Pickled / Mill Finish

- None (Bare/Polished Surface)

- Stub End

- Silver

- Varies as per size

- Stub End

- Customized as per requirement

- Used in piping systems for flanged joints

- Pipe Fitting

- 515 MPa (for 304 grade)

- 304, 304L, 316, 316L

- Pipe Fittings, Flange Connections, Industrial Piping

- ASTM A403 / ASME SA403 / DIN / EN

- Standard and customized sizes available

- Cr: 18-20%, Ni: 8-12%, Mo: 2-3% (316/316L grades)

- Stainless Steel

- 201 HB (for 304)

- Polished / Pickled

- Yes

- 304 / 316 / 316L or as specified

- Yes

- 1.0 mm to 12 mm (as per requirement)

Stubend Fitting Trade Information

- 1000 , , Unit Per Month

- 15 Days

Product Description

Stubend Fitting is widely used in process of piping and provides the highest level of joint integrity and used in high pressure and temperature applications. It is available in different specifications and thickness, which can be customized as per the needs of our valued customers. This fitting is made under the guidance of our experts by using latest technologies in compliance with industrial norms. Our offered Stubend Fitting is known for their unique features zero tolerance and accurate dimensions.

- Type: Seamless / welded/ fabricated

- Range: 2"Nb to 18"Nb in sch: 20, 40, std, 60, 80, xs, 100, 120, 140, 160, xxs available with nace mr 01-75

- Form: Long radius bend, industrial long radius bend, piggable bend, induction bend

- Radius( r ): 3d, 5d, 6d, 8d, 10d & 20d.

- Stainless steel long radius bends: Standard: astm / asme a/sa 403 gr wp "S" "W" " wx"

- Grade : 304, 304l, 304h, 309s, 309h, 310s, 310h, 316, 316ti, 316h, 316l, 316ln, 317, 317l, 321, 321h, 347, 347h, 904l

- Duplex steel long radius bends: Standard: astm / asme sa 815

- Grade: uns no.S 31803, s 32205

- Aluminium long radius bends:Standard:astm / asme sb241

- Grade: 3003 h18 , 3003 h112, 6061 t6, 6063 t6, 6351 t5, 6351 t6

- Titanium long radius bends: Standard:astm / asme sb337, sb338, sb861, sb862

- Grade: gr1,gr2,gr5,gr7,g9,gr12, gr23

- Carbon steel long radius bends:Standard: astm a 234 wpb /mss-sp-75

- Grade: wpbw, wphy 42, wphy 46, wphy 52, wph 60, wphy 65 & wphy 70.

- Low temperature carbon steel: Standard: a420 wpl3/a420 wpl6

- Alloy steel long radius bends: Standard:astm / asme a/sa 234

- Grade : wp 1, wp 5, wp 9, wp 11, wp 12, wp 22, wp 23, wp 91.

High-Quality Material and Standards

Our Stubend Fittings are crafted from top-grade stainless steel (304, 304L, 316, 316L), ensuring exceptional durability, corrosion, and heat resistance up to 870C. They strictly adhere to international standards such as ASTM A403, ASME SA403, DIN, and EN, assuring clients of reliable performance in demanding industrial applications.

Versatile Applications in Industrial Piping

These fittings are suitable for a diverse array of sectors: petrochemical, oil & gas, water treatment, and general process industries. Their adaptability to both standard and customized sizes makes them a preferred choice for pipe connections and flange assemblies, supporting a wide range of industrial requirements.

Customization and Compliance

Available in various shapes, thicknesses, and finishes, our Stub End Fittings meet specific client requirements. All products are compliant with PED, NACE MR0175, ROHS regulations, and can be supplied with export-worthy wooden packaging, making them ideal for domestic and international projects.

FAQs of Stubend Fitting:

Q: How are Stubend Fittings with Lap Joint Stub Ends typically installed?

A: Stubend Fittings are installed by butt welding the straight end to the pipe, while the flanged (lap joint) end allows a separate backing flange to be fitted for easy assembly or disassembly of the pipe system, enabling flexible and leak-proof connections.Q: What applications are Stubend Fittings most commonly used for?

A: They are widely used in industrial piping systems, including chemical plants, oil & gas refineries, water treatment facilities, and wherever flanged pipe joints are necessary. Their customizability makes them suitable for both new setups and pipe maintenance projects.Q: When should I choose a particular pressure rating (150#, 300#, 600#) for these fittings?

A: The pressure rating should match the maximum operating pressure of your piping system. Select 150#, 300#, or 600# based on the applications requirements and client specifications to ensure safety and regulatory compliance.Q: Where are these Stubend Fittings manufactured and how are they packaged for export?

A: Our Stubend Fittings are manufactured in India, using advanced forging or machining processes. For international or domestic shipping, they are packed in export-worthy wooden cases to ensure product safety and prevent damage during transit.Q: What is the lead time for Stubend Fittings if I have a custom order?

A: We maintain ready stock for standard sizes, but lead time for customized fittings depends on order specifications. Typically, production and delivery timelines are discussed and confirmed during client consultation to ensure timely project completion.Q: What benefits do Stubend Fittings offer over other types of pipe fittings?

A: Stubend Fittings provide flexibility by allowing easy disassembly for inspection or replacement, exceptional corrosion and heat resistance, adherence to international standards, and compatibility with a wide range of flanges and piping systems.Q: How are the dimensions and weight determined for these Stubend Fittings?

A: Dimensions such as length, width, height, and wall thickness are customized as per client requirements or referenced standards. The weight of each fitting varies depending on its size and material grade, which is specified at the time of order.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free