Welcome to Our Company

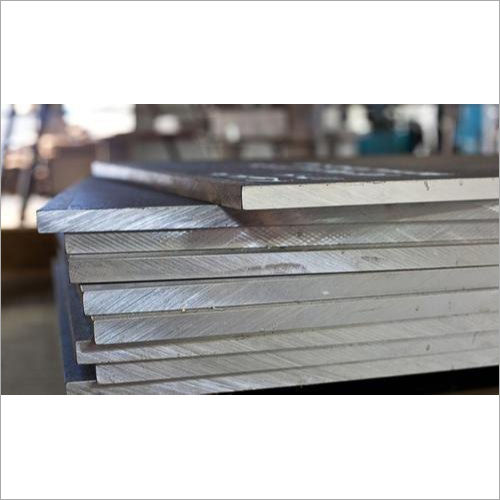

Stainless Steel Circle

300 INR/Kilograms

Product Details:

- Recyclable Yes

- Coating Type No coating / Mirror/Matte Finish

- Diameter 50 mm to 1200 mm

- Material Composition % Cr 18-25%, Ni 8-20%, Fe Balance

- Product Form Circle Cut Sheets

- Hardness Rockwell B80-B90

- Tensile Strength 520 MPa - 700 MPa

- Click to view more

X

Stainless Steel Circle Price And Quantity

- 300 INR/Kilograms

- 10 Kilograms

Stainless Steel Circle Product Specifications

- Circle

- Kitchen Utensils, Hardware, Pipe Fittings, Flanges

- Cr, Ni, Fe, C

- Custom sizes

- 520 MPa - 700 MPa

- Rockwell B80-B90

- ASTM, AISI, DIN, EN

- Circle Cut Sheets

- Cr 18-25%, Ni 8-20%, Fe Balance

- Industrial, Fabrication, Construction, Automotive, Kitchenware

- 50 mm to 1200 mm

- No coating / Mirror/Matte Finish

- Yes

- Customizable as per requirement

- Polished / Unpolished

- Silver/Grey

- Yes

- Depends on size and thickness

- Up to 870C

- Plate / Circle

- Mirror, Matte, 2B, BA

- Stainless Steel

- 304, 316, 202

- 304, 316L, 202, 430, etc.

- 1 mm to 50 mm

- Stainless Steel Circle

Stainless Steel Circle Trade Information

- 100000 Kilograms Per Week

- 1 Days

Product Description

Specification

| Material | Stainless Steel |

| Application | Oil & Gas Industry, Pharmaceutical / Chemical Industry, Automobile Industry |

| Surface Finish | Powder Coated |

| Material Grade | SS304 |

| Shape | Round |

Precision and Quality

Manufactured under stringent quality controls, these stainless steel circles offer cutting tolerances of 0.5 mm and are available in polished or unpolished finishes such as mirror, matte, 2B, and BA. They deliver consistent performance and appearance, suitable for applications requiring high reliability and durability.

Customizable for Your Needs

Available in a wide range of thicknesses (1 mm to 50 mm) and diameters (50 mm to 1200 mm), each stainless steel circle can be tailored to fit specific project requirements. Dimensions and finish types can be customized, ensuring compatibility with diverse industrial, construction, and consumer applications.

Ideal for Harsh Environments

With excellent chemical and corrosion resistance and robust heat tolerance up to 870C, these circles are ideal for demanding settings. They are suitable for use in automotive, construction, kitchenware, and hardware, ensuring longevity even in aggressive conditions.

FAQ's of Stainless Steel Circle:

Q: How are the edge types of the Stainless Steel Circle created?

A: The edge types-including plain, sheared, and laser cut-are produced by specific cutting processes that utilize machinery or laser technology to achieve precise finishes and tolerances of 0.5 mm, ensuring a clean and accurate profile.Q: What grades of stainless steel are available for these circles?

A: These circles are available in grades 304, 316, 202, 430, and others. Grades 304 and 316 are non-magnetic and provide superior corrosion and heat resistance, while grades like 202 and 430 offer versatility at different price points.Q: When should I choose a polished or unpolished finish?

A: Choose a polished finish, such as mirror, matte, 2B, or BA, for applications requiring aesthetic appeal or a smoother surface, such as kitchenware and architectural features. Unpolished finishes suit functional industrial purposes where appearance is less critical.Q: Where can Stainless Steel Circles be used?

A: They are widely used in manufacturing kitchen utensils, hardware, pipe fittings, flanges, and components for fabrication, industrial, construction, and automotive sectors due to their strength, corrosion resistance, and versatility.Q: What is the process for customizing diameter, thickness, or finish?

A: Customers can specify their requirements for diameter (50 mm to 1200 mm), thickness (1 mm to 50 mm), and desired finish. The manufacturing team then produces the circles according to these specifications, providing flexibility for unique project needs.Q: How does the chemical composition enhance performance?

A: The circles contain chromium (18-25%) and nickel (8-20%), which, along with iron and trace carbon, ensure excellent corrosion resistance, tensile strength of 520-700 MPa, and heat resistance, making them suitable for aggressive and high-temperature environments.Q: What are the main benefits of using Stainless Steel Circles?

A: Key benefits include outstanding corrosion and heat resistance, high recyclability, customizable sizes and finishes, compliance with global standards (ASTM, AISI, DIN, EN), and suitability for a broad range of industrial and domestic applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email