Aerospace Aluminium Bar

Product Details:

- Features Lightweight, durable, machinable, crack resistant

- Usage & Applications Aircraft frames, wings, fuselage, landing gear, structural components

- Cross Dimension Round, square, flat profiles available

- Outer Diameter 6mm to 300mm

- Diameter 6mm to 300mm

- Width Custom widths as specified

- Size Custom sizes: Diameter 6mm to 300mm

- Click to view more

Aerospace Aluminium Bar Price And Quantity

- 100 Ton

- 1000 INR

- 503 MPa (73,000 psi)

- Export Sea-worthy Packing

- 71.7 GPa

- 477635C

- Excellent

- 130 W/mK

- Up to 572 MPa (83,000 psi)

- 2.81 g/cm

- Solution Heat Treated and Artificially Aged

- 11% min

Aerospace Aluminium Bar Product Specifications

- 3mm to 120mm

- Customizable: up to 6 meters

- Aerospace standard AMS 4027/AMS 4047/BS EN 485

- T6, T651, O, T73, T7651

- Extruded & rolled

- 6061, 7075, 2024, 7050 aluminium alloys

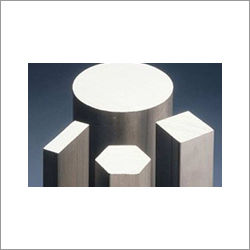

- Round, square, rectangular, hexagonal

- Aerospace Aluminium Bar

- Excellent corrosion resistance

- 6061, 7075, 2024, 7050

- Aerospace grade aluminium

- High tensile strength (Yield: up to 570 MPa for 7075-T6)

- Mill finish, brushed, anodized

- Customizable; typical length: 1m, 2m, 3m

- Custom sizes: Diameter 6mm to 300mm

- Brinell hardness up to 150 HB

- Round, square, flat profiles available

- 6mm to 300mm

- 6mm to 300mm

- Custom widths as specified

- Natural silver, custom finishes available

- Lightweight, durable, machinable, crack resistant

- Aircraft frames, wings, fuselage, landing gear, structural components

- Mill finish, anodized, polished, brushed

- 503 MPa (73,000 psi)

- Export Sea-worthy Packing

- 71.7 GPa

- 477635C

- Excellent

- 130 W/mK

- Up to 572 MPa (83,000 psi)

- 2.81 g/cm

- Solution Heat Treated and Artificially Aged

- 11% min

Aerospace Aluminium Bar Trade Information

- 1000 Ton Per Month

- 15 Days

- No

- Western Europe, Eastern Europe, Middle East, Asia

Product Description

Aerospace Aluminium Bar

We have become the leading exporter and importer of Aerospace Aluminium Bar that are widely used for both aerospace and commercial applications. It has excellent resistance to corrosion, which allows its use without any kind of protection. Apart from this, our aluminium bar has excellent ability to transmit heat instantly and productively that make it a perfect material for the heat transfer processes. Our bars are available in variety of tempers. We make sure to source all the bars from reputed patrons and deliver the aerospace aluminium bar within the stipulated time period. This makes our product highly demanding in the marketplace.

- Aerospace

- Commercial Transportation

- Building & Construction

- Infrastructure

- Electrical

- Renewable Energy

- Mass Transportation

Grades

- 2024 & 7075

Engineered for the Aerospace Industry

Our aerospace aluminium bars are designed to perform under demanding conditions. Produced using advanced extrusion and rolling processes, they achieve outstanding mechanical properties like high tensile and yield strength. Compliant with aerospace grades and standards, these bars ensure safety and reliability in structural components for modern aircraft.

Superior Strength and Machinability

With yield strength up to 570 MPa (for 7075-T6), these aluminium bars offer an excellent balance between strength and lightweight performance. Their excellent machinability allows for precise shaping and fabrication, making them a favorite choice for custom aerospace engineering projects.

Customizable Dimensions and Finishes

We provide complete flexibility in size and shape: round, square, rectangular, and hexagonal profiles are available, with diameters from 6mm to 300mm and lengths up to 6 meters. Choose from various finishes such as mill finish, anodized, polished, or brushed, and customize the appearance to match your specifications.

FAQs of Aerospace Aluminium Bar:

Q: How are aerospace aluminium bars typically used?

A: Aerospace aluminium bars are widely used in aircraft manufacturing for frames, wings, fuselage sections, landing gear, and other structural components, thanks to their high strength-to-weight ratio, durability, and resistance to corrosion.Q: What makes these aluminium bars suitable for aerospace applications?

A: Their high tensile and yield strengths, lightweight nature, excellent machinability, and compliance with aerospace standards (AMS 4027/4047/BS EN 485) make them ideal for demanding aerospace environments where performance and reliability are critical.Q: When should I choose specific grades like 6061, 7075, 2024, or 7050?

A: You should choose the grade based on your applications requirements. 7075 offers the highest strength, 6061 is versatile and corrosion-resistant, 2024 provides good fatigue resistance, and 7050 balances high strength with improved stress corrosion resistance.Q: Where are these aluminium bars manufactured and supplied from?

A: These bars are produced in India by reputable manufacturers, suppliers, and exporters who offer a full range of dimensions, grades, and finishes to meet various aerospace and industrial requirements.Q: What is the process for fabricating these bars?

A: The bars are typically extruded and rolled, then subjected to heat treatment processes such as solution heat treating and artificial aging (tempers like T6, T651, T73, T7651) to enhance mechanical properties. Surface treatments such as anodizing can also be applied for added protection.Q: How does the packaging ensure the bars remain undamaged during shipping?

A: Aerospace aluminium bars are packed in export-standard, sea-worthy packaging that safeguards against corrosion, deformation, and other damage during long-distance transit, ensuring they arrive in perfect condition.Q: What are the main benefits of using aerospace-grade aluminium bars?

A: They offer lightweight construction, superior strength, excellent corrosion resistance, high machinability, and customization in size and finish, resulting in lower overall aircraft weight and enhanced structural integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+