Aluminium Pipes

260 INR/Kilograms

Product Details:

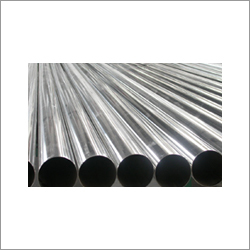

- Length Up to 6 meters or customized

- Fabrication Process Extruded, Seamless, Welded

- Outer Diameter 6 mm to 300 mm

- Finish Smooth, Satin, Brushed, Mirror

- Material Aluminium

- Cross Dimension Round, Square, Rectangular, Oval, Customized

- Material Grade 6000 series, 1000 series, 2000 series, 3000 series, 7000 series

- Click to view more

X

Aluminium Pipes Price And Quantity

- 260 INR/Kilograms

- 1000 Kilograms

Aluminium Pipes Product Specifications

- Smooth, Satin, Brushed, Mirror

- Extruded, Seamless, Welded

- 6 mm to 300 mm

- Silver, Black, Bronze or customized

- Aluminium

- Up to 6 meters or customized

- Round, Square, Rectangular, Oval, Customized

- Aluminium Pipes

- High tensile and yield strength

- Yes (various grades available)

- 60-90 HB

- T4, T5, T6, T651, O, H112

- Automotive, Construction, Furniture, Aerospace, Marine, Engineering, Electrical, General Fabrication

- Customized as per requirement

- Anodized, Mill Finish, Powder Coated, Polished

- 6000 series, 1000 series, 2000 series, 3000 series, 7000 series

- 0.5 mm to 25 mm or customized

- Round, Square, Rectangular, Oval, Customized

- 6 mm to 300 mm

- Lightweight, Durable, Good weldability, Good conductivity, Anti-corrosive

- 6061, 6082, 6063, 3003, 1100, 2014, 2024, 7075

- Yes

- 1/2 to 12 (outer diameter), customized

Aluminium Pipes Trade Information

- 1000 Kilograms Per Month

- 15 Days

Product Description

Aluminium Pipes

We are engaged in the process of exporting and importing the ideal range of Aluminium Pipes, which are seamless and robust in construction, which are free any kind of corrosion. Apart from this, the tubes are fabricated in varied sizes as per clients requirements. The alumunium pipes are used in various industries including oil and gas, chemical industry and conveying water. We offer the pipes at competitive pricing and deliver them within the given time frame to end-customers, maintaining all the quality standards.

Grades

- 5083, 5086, 6061, 6063 & 6082

Product details

|

Material |

Aluminum |

|

Unit Length |

12 m |

|

Surface Finish |

Anodized |

|

Shape |

Round |

|

Color |

Silver |

Precision Tolerance and Versatile Standards

Our aluminium pipes are manufactured in compliance with international standards like ASTM B241, ASTM B221, EN AW-6061, and IS 4922, and with a close tolerance of 0.2 mm. This ensures exceptional dimensional accuracy and compatibility with global quality requirements, making them ideal for demanding engineering and fabrication applications.

Multiple Grades and Surface Options

Choose from a comprehensive selection of major aluminium grades6000, 1000, 2000, 3000, and 7000 seriesengineered for both strength and formability. Accentuate your project with surface treatments such as anodized, powder coated, mill finish, or polished, achieving both functional and aesthetic goals. Custom color options ensure your precise requirements are met.

Packing and Delivery for Global Requirements

Aluminium pipes are carefully packed in plastic wraps, bundles, or sturdy wooden crates, following export-standard protocols for optimum protection during transit. With a minimum order quantity of 100 kg and customized lengths or dimensions available, these pipes serve dealers, distributors, manufacturers, and end-users across India and international markets.

FAQs of Aluminium Pipes:

Q: How are the different end types of aluminium pipes chosen for various applications?

A: End types such as plain, beveled, and threaded are selected based on the pipes intended application. Plain ends are commonly used for welding or slip fittings, beveled ends facilitate welding joints, and threaded ends are best for quick installation or removable connections, as seen in plumbing, structural, or fabrication projects.Q: What standards do your aluminium pipes comply with and why is this significant?

A: Our aluminium pipes are produced according to ASTM B241, ASTM B221, EN AW-6061, and IS 4922 standards. Adhering to these ensures product reliability, global compatibility, and precise performance in critical sectors like aerospace, engineering, and construction.Q: When should I consider specific aluminium alloys like 6061, 6082, or 7075?

A: Selecting a suitable alloy depends on the mechanical properties required. Grade 6061 is excellent for general fabrication and structural use, 6082 offers higher strength for heavy-duty engineering, and 7075 is preferred for high-stress aerospace and military applications due to its superior tensile strength.Q: Where can aluminium pipes with customized dimensions and finishes be used?

A: Customised aluminium pipes can be used in diverse applications, including electrical conduits, construction frameworks, furniture manufacturing, marine installations, and automotive components. The customizable features ensure a perfect fit for your specific project needs.Q: What is the typical process for fabricating aluminium pipes and what forms are available?

A: Aluminium pipes are fabricated using extrusion, seamless, or welded processes to achieve the desired strength and consistency. They are available in straight, coiled, or cut-to-length forms, with dimensions and shapes fully customizable as per your requirements.Q: How does aluminiums corrosion resistance and conductivity benefit end users?

A: The anti-corrosive nature and conductivity (3438 MS/m) of our aluminium pipes make them ideal for outdoor, marine, and electrical applications. These features ensure a longer service life, reliable performance, and reduced maintenance costs compared to other metals.Q: What is the minimum order quantity, and how are aluminium pipes packed for export?

A: The minimum order quantity for aluminium pipes is 100 kg. For safe delivery, products are packed using plastic wraps, bundles, or sturdy wooden crates, meeting stringent export quality standards to protect the pipes during international and domestic transportation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email